Here at C&H Plastics we use 18 different injection molding machines so we can mold a variety of parts. So, what are the basics of a thermoplastic injection molding machine?

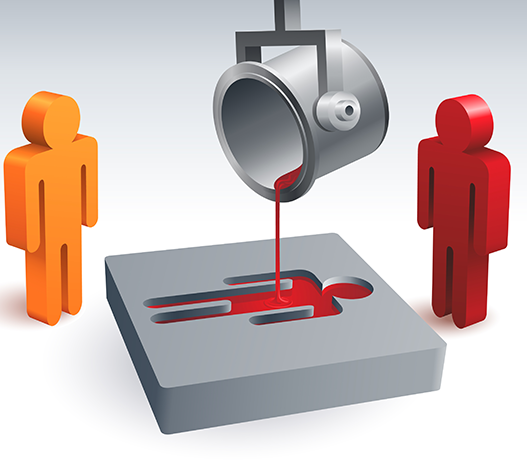

In general, injection molding is a manufacturing process that produces parts from thermoplastic plastic materials. We feed the material into a hopper, melt it in a barrel, then force it with a screw into a mold cavity. There it cools and hardens to the shape of the mold cavity.

All of this happens in an injection molding machine or injection press. We use electric, hybrid, and hydraulic machines in our manufacturing plant.

Molding machines perform five basic steps to convert the thermoplastics into a plastic part. They are:

Step 1: Melting the polymer

Step 2: Conveying the molten polymer

Step 3: Shaping the molten polymer in the mold

Step 4: Cooling the shaped polymer

Step 5: Removal of the solidified finished or semi-finished plastic part.

We adjust the settings on our machines for each job. Each injection molding machine has adjustments such as barrel temperature settings, injection pressure, injection speed, and clamp force. The mold can also be equipped with a temperature control unit to aide in cooling or heating the mold as needed in this process.

All of these adjustments are there to deal with the variables of plastic molecules traveling through the machine. These variables in the plastic molecules include the melt temperature, viscosity, pressure, and cooling rate.

As we’ve discussed in earlier posts, the mold tooling is professionally designed and engineered to the specs of the plastic part. We accommodate all the variables in the plastics and settings on the machines with a comprehensive quality assurance program. We’ll talk about that in an upcoming post.

Until next time,

Rollin

Rollin Bateman is VP of Sales and Engineering at C&H Plastics, Inc. He is the guy to talk to regarding your new projects and ideas. He assists with designs, prototyping, manufacturing, and assembly. Call him at (315) 841.4101 ext. 29 or email here.